The Role of 3D Printing in Modern Manufacturing Solutions

- Aug 1, 2025

- 3 min read

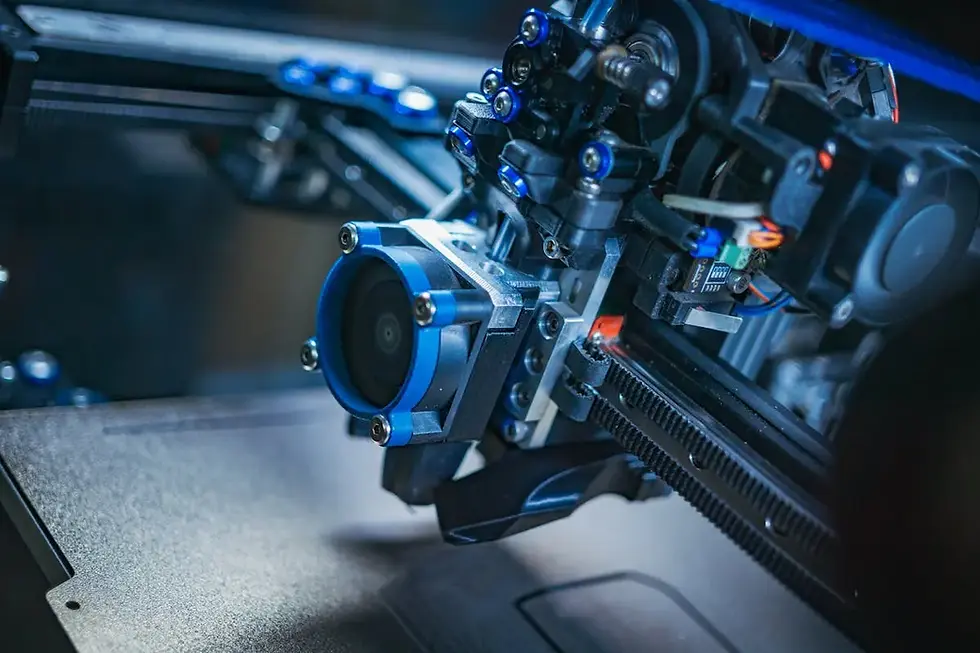

In recent years, 3D printing has emerged as a groundbreaking technology poised to revolutionize the manufacturing industry. Known for its flexibility and efficiency, 3D printing offers modern solutions that reshape how products are designed, produced, and delivered. This blog will explore the integral role 3D printing plays in today's manufacturing landscape, and how it is set to drive future innovations.

Understanding 3D Printing Technology

To appreciate the role of 3D printing in manufacturing, it’s essential to understand how this technology works. 3D printing, or additive manufacturing, creates objects layer by layer from digital models. This process enables unique design possibilities and the production of complex geometries that traditional methods cannot achieve.

One of the key distinguishing factors of 3D printing technology is its ability to transcend the design limitations imposed by traditional manufacturing. Unlike conventional methods that often require multiple steps, 3D printing consolidates the production process, allowing for intricate internal structures and hollow designs that are impossible or expensive to accomplish otherwise. This shift is transforming industries by promoting design freedom and efficiency, ultimately leading to cost savings and faster production cycles.

The Benefits of 3D Printing in Manufacturing

One of the most significant advantages of 3D printing is its capability for customization. Manufacturers can produce small batches of personalized products efficiently. Additionally, 3D printing reduces material waste, lowers production costs, and shortens lead times, making it a cost-effective solution for many industries.

Moreover, 3D printing enhances supply chain resilience by enabling localized production. During times of disruption, such as natural disasters or global pandemics, manufacturers can mitigate risks by producing parts on-site rather than relying solely on distant suppliers. This approach not only reduces logistic complexity but also contributes to environmental sustainability by minimizing transportation emissions. The integration of digital manufacturing solutions like 3D printing is thus contributing to a more agile and adaptive manufacturing ecosystem.

Transforming Product Development and Prototyping

In product development, speed and innovation are crucial. 3D printing allows for rapid prototyping, enabling designers and engineers to test and refine their ideas quickly. This accelerates the design process, improves product quality, and enhances creativity by allowing iterative feedback and swift modifications.

The ability to iterate designs with ease is drastically changing research and development in engineering fields. For instance, complex elements such as intricate cooling channels and ergonomic structures can be effectively trialed and tested. Not only does this lessen the barrier for creativity and experimentation, but it also levels the playing field between large enterprises and smaller innovators. With 3D printing, a startup can now develop, prototype, and bring to market a product with far fewer resources than previously needed.

Applications Across Various Industries

From aerospace to healthcare, 3D printing is making waves in various industries. Aerospace companies utilize it for lightweight component fabrication, while the healthcare sector leverages 3D printing for creating prosthetics and implants tailored to individual patients. Its versatility demonstrates its potential to drive industry-specific advancements.

The automotive industry also benefits from 3D printing, especially in the realm of prototyping new parts and creating hard-to-find replacement components. This adaptability is mirrored in fashion, where designers push the boundaries of textile creation by exploring avant-garde shapes and sustainable materials. Educators, too, are seizing the moment by utilizing 3D printing as a hands-on tool for learning, reinforcing STEM concepts through real-time creation and experimentation.

The Future of 3D Printing in Manufacturing

As technology advances, the future of 3D printing looks promising. With ongoing research and development, we can expect new materials, improved printing speeds, and reduced costs. This evolution will likely further integrate 3D printing into mainstream manufacturing, paving the way for more innovative and sustainable solutions.

Anticipating the future, partnerships between traditional manufacturing and tech innovators are expanding the potential applications of 3D printing. From developing new materials that break conventional limits to refining printing at the molecular level, the roadmap ahead promises exciting breakthroughs. For businesses ready to embrace change, the horizon is full of opportunity, laying groundwork for dynamic business models and revolutionary product offerings.

Embracing the Future of Manufacturing with 3D Printing

3D printing is undeniably a catalyst for transformation within the manufacturing sector. By embracing these advances, companies are not only enhancing their production capabilities but also fostering innovation and sustainability. As 3D printing technology continues to evolve, it promises even greater potential for future manufacturing solutions.