Stereolithography (SLA)

Stereolithography (SLA) is a 3D printing technology that is most commonly known for its ability to provide high dimensional accuracy and superior surface quality. With these benefits over other types of 3D printing, it may come as a surprise that SLA was actually the first 3D printing technology developed and it was first patented in the mid 1980s. The main limitation for many years has been high operating costs and limited materials. However, over the past decade there have been significant advancements that have reduced these costs, and the materials library now available for this technology is one of the most diverse.

Like most other technologies, the concept for generating a 3D part using SLA is based around the fundamental idea of stacking small, mostly 2D layers on top of each other - the primary difference is the type of material being used and the method of creating each layer. In the case of SLA, the raw material is a photopolymer which is a type of polymer that undergoes a chemical reaction when exposed to light. An SLA 3D printer uses a laser as a light source and combines a series of mirrors and/or motion systems to precisely control this photopolymer chemical reaction to solidify each layer.

Although stereolithography (SLA) specifically refers to photopolymer 3D printer that use a laser, the term is commonly used to refer to all photopolymer 3D printers which may incorporate other light sources to initiate the reaction such as LCD, LED, or DLP. The different types of light sources can generate some pros and cons. For example, LEDs solidify the entire layers at the same time, whereas the laser has to "draw" the layer. This makes LEDs faster in most cases, but the individual LED pixels can sometimes been seen manifested in the part, depending on the resolution.

At i-SOLIDS we utilize both open-source photopolymer 3D printers which can be good for lower costs and we also have a larger fleet of Formlabs SLA printers. Formlabs is well known the industry for its ability to provide consistent results and a diverse, engineering grade materials library.

Already have a 3D model and want to get a quote on Stereolithography services?

Materials: Standard, Clear, High Temp, Tough, Durable, Rigid, Flexible, Elastic, ESD Safe, etc. <-- Learn More

Standard Dimensional Accuracy: ± 0.5% with a lower limit of ± 0.15 mm (± 0.006")

Post Processing Options: Threaded Inserts, Sanding, Painting, Coating

Design & Production Considerations:

-

Diverse engineering grade material library with options available to simulate almost all types of polymers

-

Most parts require printing on a very thin support structure that can leave small "pits" when removed. These pits are typically removed during standard post processing, but it is preferred to orient parts with cosmetic surfaces away from supports

-

Although the printer is capable of generating extremely high accuracy, the inherent properties of many materials make some parts susceptible to distortion or warping during the final curing process.

-

The parts are printed in a resin vat, which can trap liquid resin if there is any hollow geometry without a hole to allow the resin to drain out during post processing

Ideal Applications:

-

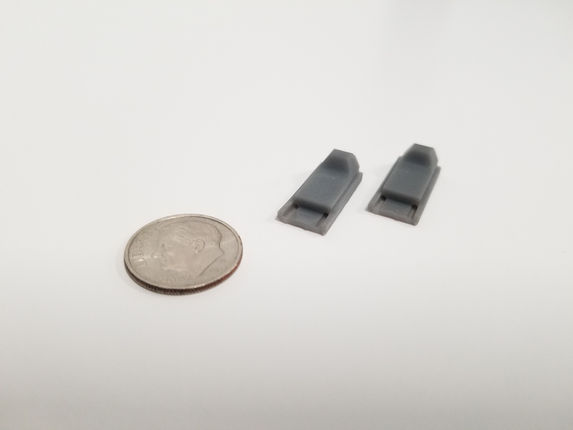

Relatively small parts (less than 6") that require high accuracy

-

Parts requiring unique materials properties

-

Great for custom jewelry, dental modeling, surgical guides, high temperature molds, etc.

Example Gallery: